In any supply chain, you may choose either wood or plastic pallets. The two types of pallets have both advantages and disadvantages, depending on when/where you intend to use them.

This is a HDPE plastic pallet.

This is a wood pallet.

For the scope of this article, I will take you through unbiased and in-depth analysis on how to cut cost in your next supply chain, either by using plastic pallets or wood pallets.

Remember, at any given point, your main focus should be the return on investment (ROI). And, you can easily do this by choosing the right pallet.

Here is how you can go about it:

1. Understand Your Industry

It makes a lot of sense to use plastic pallets in closed-loop warehouse. This is because the pallets will be returned to you after use.

Remember, the initial cost of plastic pallets is slightly higher (almost twice that of wood pallets). Therefore, it won’t make any economic sense to buy a plastic pallet, and then use it only once.

Definitely, this will increase the operational costs that will be paid for by the end user to ensure you remain within the profit margin. As a result, you may not compete favorably in the market.

These plastic pallets are designed for different applications.

Since plastic pallets are durable and can withstand rigorous heavy duty use; by retaining them, your company will maintain consistent costs.

This will be to your advantage since you don’t have to invest in new pallets.

2. Determine the Average Weight (Load) You Want to Ship or Store

Both wood and plastic pallets have different load capacities. The load capacity depends on many factors such as the structure of the pallet or type of material.

For example, a plastic pallet made from 100% virgin HDPE is stronger than the one made from recycled plastic material. Assuming all the two plastic pallets are of the same size, design and structure.

Normally, there are three key aspects of a pallet load capacity. These include:

- Dynamic load capacity; it is the maximum weight a pallet can hold when raised either by a hand jack or forklift.

- Static load capacity; the maximum load a pallet can hold when in a fixed position or at rest on a level surface.

- Racking load capacity; this the maximum load a pallet can hold when supported on only two sides. That is, the maximum weight it can hold on a racking system.

Generally, wooden pallets will hold more weight than plastic pallets. Normally, plastic pallets are suitable for loads of about 1,500 pounds or less.

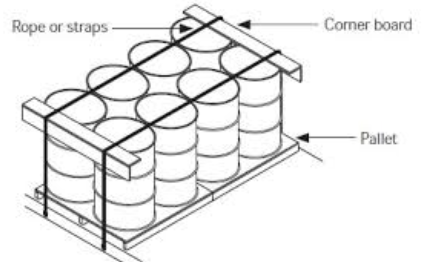

These are drums on a pellet.

On the other hand, wood pallets are suitable for heavy loads.

The aspect of weight is important in the sense that, you will choose the right pallet that will carry the load without breaking. It can be catastrophic if a pallet breaks when carrying products.

3. Audit Your Pallet Management System

This is a critical aspect that most businesses ignore, yet it directly affects the cost of shipping and storage. I had already discussed one aspect of auditing pallet management system.

That is, for a closed-loop system, the best idea is to invest in plastic pallets. This will be a cheaper option in the long run.

In case you intend to ship products overseas, you should use wood pallets. This is because you will not get them back.

These are wooden pallets carrying heavy load.

Since wood pallets are cheaper than plastic pallets, in this case it makes economic sense to use them for international shipping. However, you should ensure that they comply with the ISPM -15 regulations.

Another option that I consider viable is using pallets from a third party. That is, get pallets that you can pay per trip and not per pallet.

To make business sense of this, you can transfer this cost to the consumer. I have seen a number of companies adopt this method and it works well for them.

In short, all I am trying to say is, never ship products with your durable plastic pallets if you will not get them back. You should use plastic pallets if the consumer is willing to pay for their cost.

4. Consider the Type of Product You’re Shipping

A good number of individuals find it difficult to make the right decision here. Let me be clear about this:

In any supply chain process, your main intention is to ensure the product reaches its destination safely. Any damages or contamination will translate to extra operational costs in terms of replacement or compensation.

I’ll summarize what you need to do:

- Use plastic pallets to ship fragile products since they don’t have fasteners, screws or nails that may damage the products.

- Plastic pallets are recommended for shipping products in situations where hygiene is a priority. It is easier and cheaper to maintain their hygiene by hot washing, chemical sterilization or steaming. Furthermore, they are resistant to most chemicals and prevent fungus/bacteria growth.

The process of loading plastic pellets.

NOTE: Always remember to use these plastic pallets only if you’re sure they will be returned back to you.

5. Think of Any Possible Repair Costs

Even though a plastic pallet will serve you for over 10 years, at some point it may get damaged. Therefore, you’ll have no option but to recycle them again.

That is, you need to melt and mold the pallets a fresh. This is a cumbersome and expensive process since it requires technical expertise.

But, the good thing is, the plastic will never go to waste. You will eventually bring them back to the system.

This is the reason why they are considered to be eco-friendly.

On the other hand, wood pallets can easily be repaired. The process is not costly since it involves replacing a few parts or reinforcing it.

These are old and broken wood ballets.

However, it reaches a point where you cannot recycle or repair them anymore. This is a major disadvantage.

6. Be Specific on What You Intend to Use the Pallet For

In case you need a dual purpose pallet, then plastic pallet is a cost effective alternative. By this I mean; you can use the pallet to ship product and use it in a store display.

A plastic pallet used in displaying products.

This is a common aspect in grocery or electronic industries. That is, the dealer displays the product while placed on a pallet after which it can be returned to the distributor.

Conclusion

Clearly, getting to a point where you can settle for either a plastic pallet or wood pallet really needs careful analysis of every situation at hand. You need to examine trade off costs.

That is; what are you going to gain by compromising a certain aspects?

By the end of it all, you should strive to remain competitive in the market, make realistic profits and ensure customer satisfaction.

Just in case you find it difficult to make the right decision; I can help you based on the limited options at your disposal.

86-137-1715-1153

86-137-1715-1153