Adopting an efficient supply chain system is the desire of every business owner. That is, having the capacity to store, ship and deliver products as scheduled within the limited resources available.

So, how can you achieve this successfully?

In this article, I am going to show you how to increase supply chain efficiency with plastic pallets.

Shipping pallets have been around for years with wooden pallets being popular in most industries. However, a number of suppliers and businesses have changed to plastic shipping pallets.

There are so many reasons behind with one of them being increased efficiency in product handling.

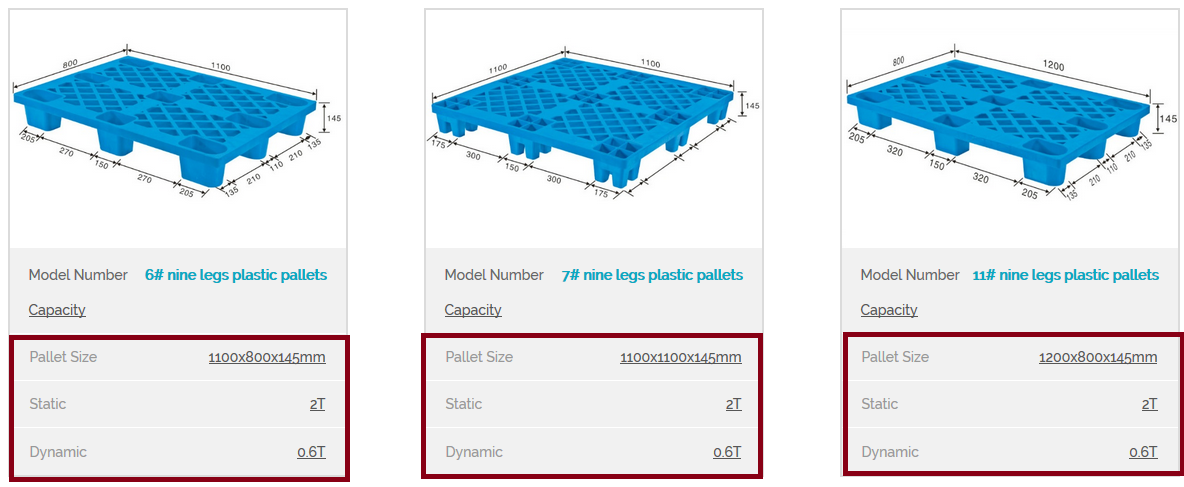

These are three different types of plastic pallet designs.

Below are 6 ways a plastic shipping pallet can increase efficiency in the supply chain:

1. Focus on Long-term Cost Saving

I want you to get this clear from the start.

Choosing a pallet in any supply chain will depend on your industry. With this knowledge, it will be easier to focus on long-term cost saving.

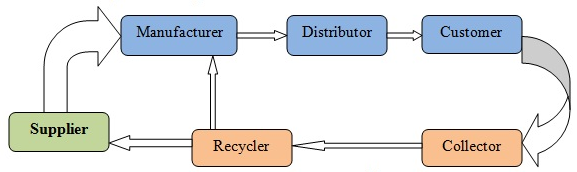

That is, in case you’re planning to operate in closed-loop supply chain, then I will recommend plastic pallets. With this, you will save a lot of money.

This is a simple closed-loop supply chain. Image source: MBASKOOL

In such as system, you will use the plastic pallets several times. Therefore, you don’t need a pallet that will break during the process.

Here is the truth no one will tell you:

- A plastic pallet is slightly expensive (initial cost) compared to wooden pallets. However, they have long-term and rapid economic payback.

- Plastic pallets service life is over 10 years; this is over 250 trips. This is not the case for wooden pallets that will serve you between 3 to 5 years.

A number of plastic pallet manufacturers use virgin HDPE material. This is a strong and durable material.

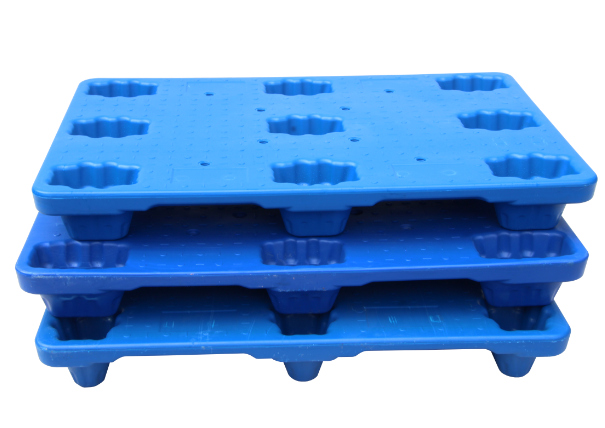

These are thermoformed plastic pallets made from virgin HDPE plastic material.

Even when you reuse these plastic pallets several times, they do not lose their dimensional stability. In case of any change, then it is very negligible.

Furthermore, after 10 years of use, you can still recycle old pallets to mold a new one of any design for your supply chain management.

Clearly, you will get value for your money. Throughout this process, there will be no delays in the entire process.

In short, plastic pallets guarantee efficiency in closed-loop supply chain such as in beverage, dairy, pharmaceutical and automotive industries, amongst others.

2. Let Safety be Your No. 1 Priority

Nothing is more annoying than handling a load that is not safe. In most cases, you will focus on taking precautions to protect yourself from possible injuries.

Obviously, this will reduce product handling efficiency.

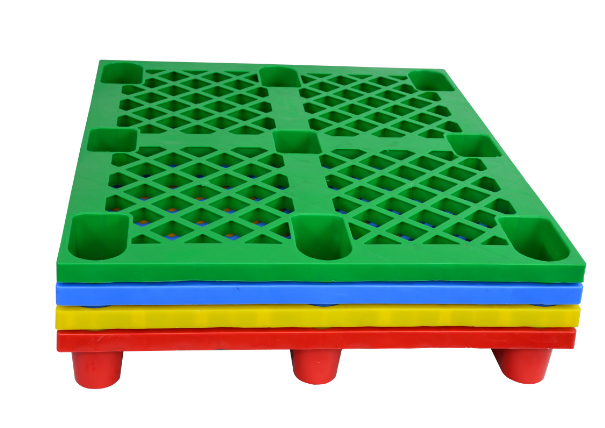

Look at these three sets of industrial plastic pallets:

These are industrial plastic pallets.

Clearly, you can see that these plastic pallets have smooth edges. There are no nails, splinters or any metallic reinforcements.

This is because there are molded from high quality virgin HDPE material.

Choosing these types of plastic molded pallets for your supply chain will guarantee efficiency. This is because the safety of plastic pallet users and that of the products will be guaranteed.

With plastic pallets, there will be no:

- Injuries hence you’ll focus on maximizing production and supply.

- Protruding nails and fasteners that can scrap goods, floor or forklift

In short, you can confidently handle products, even the most fragile ones. I am sure; this is what every business owner desires.

3. Stop Worrying about the ISPM-15 Compliance; Plastic Pallets are Not Affected by this Regulation

You cannot succeed in any venture if you have a divided attention. With plastic pallets, you don’t have to worry about many regulations and rules governing the use of wooden pallets.

I have seen many products delayed at the shipping terminals simply because the wooden pallets do not meet the required quality standards. The ISPM – 15 regulations stipulate the required treatment procedure for wooden pallets.

A number of countries globally have since adopted the ISPM – 15 regulations. This regulation aims to stop the international spread of pests and insects.

For instance, the U.S. Customs and Border Protection has strict rules and regulations pertaining to importing or exporting products using wooden pallets.

Clearly, this is a tiresome process considering that your pallets must undergo strict inspection at the border points. Remember, you may have to treat your pallets after a given duration and this can be expensive too.

Below is a video showing how to treat wooden pallets (you can see for yourself how this can be expensive for a business):

https://www.youtube.com/watch?v=KTeo10CmBlU

In short, all these may reduce your efficiency in the supply chain.

To avoid all these processes, simply acquire a plastic pallet. In case you can’t afford the new plastic pallets, there are the used or those made from recycled HDPE material.

The good thing about plastic pallets is that, once they are molded, you don’t require further treatment except for those in hygienic sensitive supply chain.

4. Maintain High Standards of Hygiene; it’s Key Supply Chain

How is this possible?

There are some industries such as foodstuff, beverage and pharmaceutical industries where hygiene is an integral aspect that you can’t ignore. It is for this reason that you need a hygienic plastic pallet.

This is a plastic pallet in the pharmaceutical industry. Image source: Pallet Evolution.

Can you remember when Johnson & Johnson’s recalled the Tylenol? This was due to a smell caused by 2, 4, 6-tribromoanisole (TBA).

TBA is a chemical used to treat wooden pallets.

For a fact, there is no reputable company that would wish to be in such a situation. This is because it will prove that your company has an inefficient supply chain system.

So, how do plastic pallets help maintain high standards of hygiene?

The key features of these pallets include:

- Surface that is easy to clean hence, reducing chances of contamination

- No hidden sections where dust can collect

- Impervious to moisture, weak acids or alkali thus, reducing chances of contamination

- Molds hardly grow on plastic surfaces

- Specialized designs are extremely smooth with sealed surfaces to prevent any possibility of contamination.

- Sterilizing plastic pallets

In short, maintaining the required hygiene standards will guarantee efficiency in the supply chain.

5. Reduce Transpiration Cost by Choosing Lightweight Plastic Pallets

Let me tell you the truth, weight is a critical aspect during transportation. Therefore, heavy wooden pallet will increase the shipping cost.

Also, a heavy pallet will require robust forklift, which can be expensive.

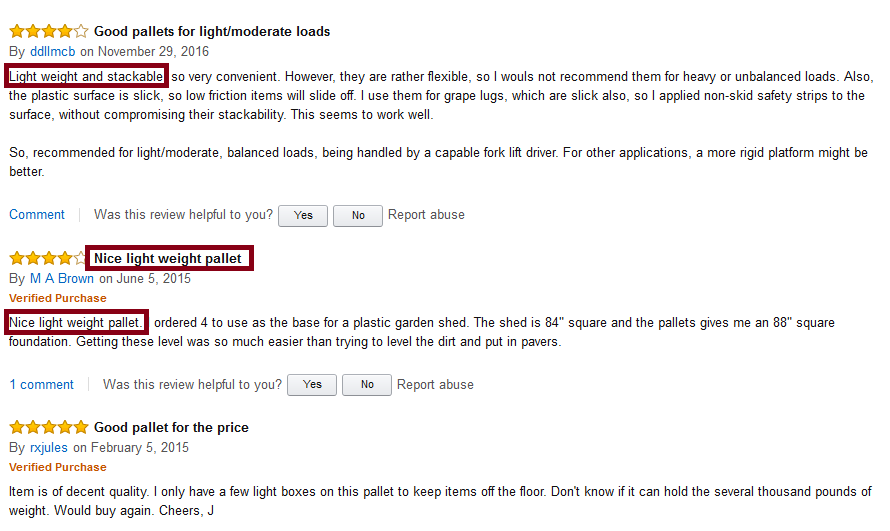

Last year, I did analyze feedback from different companies in the supply chain business. It was quite clear that the weight of a pallet determines the efficiency of either product shipping or handling.

Let me show you some of the reviews from Amazon:

A section of customer reviews.

In short, about 71% of companies opt for plastic pallets due to their lightweight. This is true because a plastic may weigh between 30% and 35% less than a wooden pallet of the same size.

Ideally, this will reduce both the shipping and handling costs. This makes it more cost effective to use plastic pallets as opposed to the wooden ones.

However, you should note that the weight of plastic pallets may vary depending on the size and intended load it should carry.

Normally, you’ll find plastic pallet manufacturer referring to both the dynamic and static load to describe the capacity of a pallet.

These are 3 different types of nine legs plastic pallets.

You can see the variation in capacity and size from the image above.

6. Save Space Where Possible; it’s a Valuable Resource

During return trip or when shipping empty plastic pallets, you can save a lot of space. This will definitely provide room to carry more pallets.

It is for this reason that most supply chain companies opt for nestable plastic pallets. You can save a reasonable amount of money when shipping empty pallets.

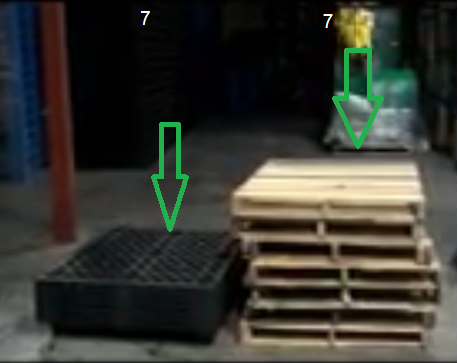

Here is a clear comparison between wooden and plastic pellets:

This image shows 7 plastic pallets (left) and 7 wooden pallets (right) stacked together.

Obviously, with these plastic pallets you can save a lot of space. Clearly, even in the warehouse, these types of plastic pallets will save a lot of space.

However, not all plastic pallets save space. Take for instance these:

This is a HDPE plastic pallet.

You will save a lot of space when you opt for nestable plastic pallets.

With all these in mind, you’re likely to increase your supply chain irrespective of your industry.

Conclusion

Clearly, plastic pallets can increase efficiency in the supply chain. When you consider all the seven aspects listed above, there is a high chance that you will get value for your money.

Again, you should know that plastic pallets come in different shapes, designs and varying load capacities. In case you’re not sure of the right plastic pallet for your industry, feel free to contact me – I’ll be happy to assist.

Further reading

Import regulations for packaging containers made from solid wood (IPPC standard) – Source: TIS

Wood packaging goods for import and export – Source: U.K. Gov.

86-137-1715-1153

86-137-1715-1153