Whether you want to custom build plastic pallets or choose from the many standard sizes available, it is important to know their intended purpose in the supply chain.

In this article, I am going to introduce you to 11 different applications of plastic pallets.

This doesn’t imply that these are the only areas where you can use this equipment.

Ideally, in any task that involves loading, offloading, storing or moving products, you will need a plastic pallet.

Here, I will not only mention the specific application, but also explore the reason why they are a perfect alternative.

Here is my list:

1. Plastic Pallet for Exporting Products

We use plastic pallets extensively in exporting and importing businesses.

At any given point, you’ll wish the product/item reaches its intended destination safely.

A plastic pallet makes loading and offloading easier and simple using lifting equipment such as forklifts or jerks.

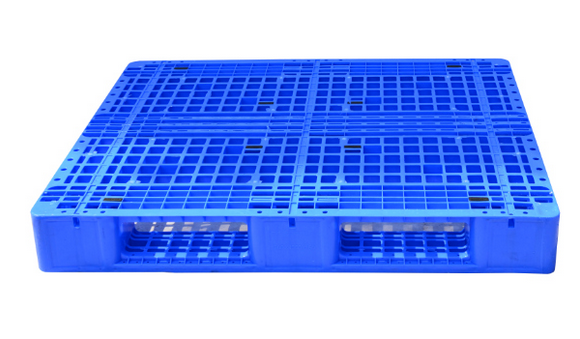

A Euro Export Plastic Pallet

However, there are a number of aspects you need to consider while choose plastic pallets for exporting applications.

For instance, are you going to get back the plastic pallets like in the case of closed loop supply chain?

If yes, then you can choose 100% virgin polypropylene (PP) or high-density polyethylene (HDPE) plastic pallets.

Even though the initial cost of these plastic pallets is high they are durable and can serve you for about 250 trips.

Alternatively, in applications of plastic pallets where they will not be returned, consider using recycled plastic.

Recycled plastic pallets are quite affordable thou not as durable as those made from virgin plastic.

Furthermore, you need to consider the export plastic pallet design.

Normally, nestable plastic pallet designs will save a lot of space (over 35%), especially on the return trip.

2. Displaying Products in Stores or Shops

Display plastic pallets are commonly used for merchandising.

These pallets reduce the risk of damaging a product when moving it from one point to another.

This is because you’ll only lift the pallet without touching the product. It is a perfect choice for delicate items in retail stores.

A display plastic pallet

Display pallets mainly come with a 4-way forklift option.

This allows for trouble-free lifting of products on the pallet from any side.

Since you’ll use these pallets within your store, consider those molded from 100% virgin HDPE material.

The HDPE plastic pallets are dimensionally stable thus they will not change their sizes, even after holding the product for a long period of time.

These plastic pallets are designed with outstanding display properties that can be customized to the specific requirements of your business.

The display pallet does not fade.

Remember, you can use these pallets for secondary packaging as well.

3. Plastic Pallets are Popular Airfreight Shipping

Light duty plastic pallets are suitable for most airfreight shipping where weight is a major concern.

Plastic pallets are about 27% lighter than wood pallets of the same size and design.

This implies that you’ll obviously save a reasonable amount of money during shipping.

Even with the lightweight, still it will not compromise on the strength of a plastic pallet – they can handle enormous weight.

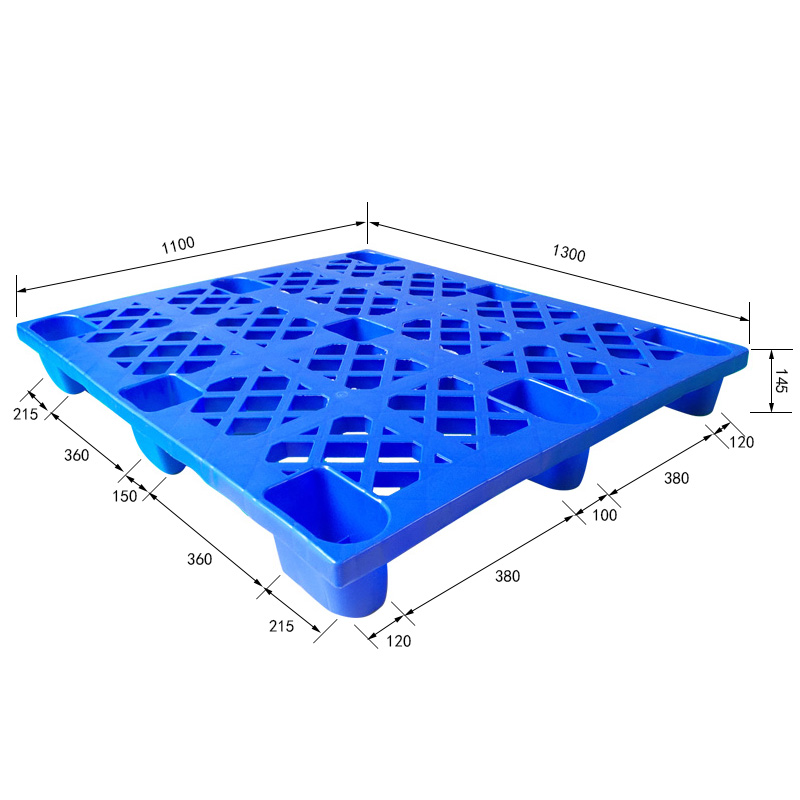

The spaces in between the pallet surface make it lighter compared to other models

With plastic pallets, you can easily modify designs (with special sizes) to fit in small aircrafts.

Remember, airfreight shipping is fast, thus, with high quality plastic pallet your product will get to its destination within the scheduled time.

Additionally, the nestable options will also save you a lot of space, hence reducing the cost of freight during return trip.

Also, you can choose from the either 100% virgin PP or HDPE plastic pallets.

4. Applications of Plastic Pallets in Pharmaceutical Industries

Here, you need a pallet with low tolerance for superior failure and hygienic properties.

Therefore, to meet these demands in this supply chain, you need pharmaceutical plastic pallets.

These are hygienic plastic pallets

Plastic pallets for pharmaceutical industries meet the strict requirements as stipulated by the FDA.

You can maintain the required sanitary conditions.

PP and HDPE plastics are chemically inert and cannot contaminate drugs when they are left for a long time.

They have no reactive chemicals that can cause contamination.

Moreover, these pallets absorb shock during transportation with some having anti-slip surface.

This ensures the pharmaceutical products are handled safely.

The 4-way forklift entry ensures convenience when loading or offloading plastic pallets with pharmaceutical products.

These plastic pallets come in different sizes and designs, with both ISO and custom design options available.

All you need is to specify the requirements for your supply chain to get an appropriate option.

5. Plastic Pallet for Use in Beverage and Foodstuff Industries

The key features of plastic pallets in the beverage and foodstuff industry is similar to that in the pharmaceutical industry.

Here, you need a plastic pallet that is easy to clean and sterilize.

It must not hide dirt or any form of contaminants such as mold.

You can easily clean these plastic pallets by splashing water on the surface.

These are lightweight, compact, durable and reliable plastic pallets that are not susceptible to failure during use.

Like other pallets, there are the standard and custom designs available.

Basically, the pharmaceutical and foodstuff plastic pallet share the same features.

6. Transporting or Shipping Drums

Do you know that there are specific types of plastic pellets designed specifically for this application?

At times, you’ll need to ship oil drums that can easily slip off the ordinary plastic pallets.

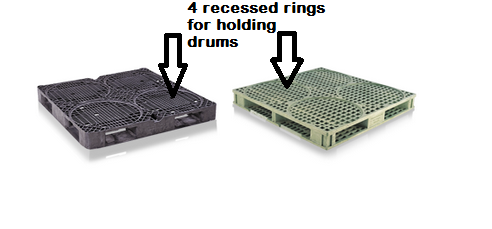

The 48″ x 48″ plastic pallets with recessed rings are popular for shipping and transporting drums.

Drum plastic pallets with recessed rings

The number of recessed rings on the plastic pallet will determine the number of drums it can hold.

Recessed rings ensure the drums don’t fall or slip during shipping.

Again, you should choose the pallet depending on the capacity of the drums you intend to carry.

Most of these pallets have 4-way forklift entry for easy access during loading and offloading.

They are available in a wide range of colors, which you can choose for easy identification.

So, depending on the specific applications of plastic pallets, you any design color or size.

7. Electronic Shipping Pallets

Electronics such as TVs, computers, electrical panel components, etc. are delicate thus you need a reliable product handling accessory.

It is for this reason that you need a high quality plastic pallet.

Depending on the type of electronics you intend to store or ship, the pallet must meet certain requirements.

Different types of electronics on plastic pallets

Quite a number of electronics are sensitive to static charges.

Therefore, you need anti-static plastic pallets.

Such plastic pallets have anti-static additives or ESD that prevent the generation and accumulation of static charges that may damage the electronics.

Plastic pallets designed to ship or store electronics are resistant to water absorption and impervious to solvents, odors, fats or acids.

Besides, they don’t have nails or screws that can scratch or damage the electronics.

In short, you can count on plastic pallets when it comes any type of shipping.

At times, it is these pallets that you can use as display pallets too.

8. Storing and Transportation in Retail Stores

Plastic pallets play an integral role in retail stores.

Depending on the kind of product you intend to store or transport, there is a need to use hygienic, durable, eco-friendly and reliable product handling equipment.

Plastic Pallets in a storage facility

With the nestable options, you’ll benefit from their space saving feature besides the ergonomic design.

Over the past decade, a number of retailers have generated a revenue stream by adopting plastic pallet in their operations.

They don’t have to worry about their product getting damaged or investing in new pallets after a few trips.

Plastic pallets in food industry guarantee over 250 trips.

Depending on your specific requirements, you can choose the custom designed plastic pallets.

Remember, custom made plastic pallets are powerful tools when it comes to marketing or branding.

You can have the retail store’s logo or name on the pallet.

9. Applications of Plastic Pallets in Shipping or Storing Chemical Products

Volatile, hazardous and corrosive chemicals can corrode your shipping container, cause injuries or damage the storage racks.

This is why you need spill control pallets or spill containment plastic pallets.

Spill control pallets are specifically designed to contain spillages or leaks during storage or leakage.

Such pallets are made from chemical resistant virgin PP or HDPE material.

They come in a wide range of shapes and designs, with those having a 4-way forklift entry being the most popular.

This allows for easy access of forklift thus easy loading and offloading.

These are spill control plastic pallets with holes that hold the leaking liquid.

Looking at this plastic pallet, you’ll realize that it has a removable spill deck.

You can remove the spill deck to clean or remove the spilled liquid.

They are easy to clean and will save you from the laborious process of cleaning the entire shipping container.

10.Product Handling in Groceries

You need plastic pallets made from the FDA approved material.

This makes the HDPE plastic pallets a perfect choice for this task.

The many benefits of plastic pallets have been the main reasons why some of the biggest supermarket chains have adopted these accessories.

This is because plastic pallets guarantee the safety of fresh vegetables and fruits without worrying about any contamination issues or pests.

Generally, grocery plastic pallets are:

- Immune to insect contamination

- Bacteria and pathogens free

- Easy to clean and sanitize

- Safe with no protruding parts or nails that may cause damage to the fruits or vegetables

- Easy to handle due to the lightweight

Furthermore, you choose the RFID plastic pallets for easy identification of products.

A nestable plastic pallet that is common in most grocery stores

Clearly, by adopting plastic pallets for your product handling procedures in groceries, there is a chance of high ROI.

No need to worry about the extra expenses associated with wood pallets.

11. Heavy Duty Industrial Product Distribution Applications

Whether it is in-house or other distribution networks, you need a strong and durable plastic pallet that can withstand heavy weight.

Although HDPE plastic pallets are strong, those made from PP plastic are harder and more rigid.

Remember, types of material play a pivotal role in applications of plastic pallets.

Plastic pallets are dimensionally stable, hence their performance does not vary with a change in weather conditions.

All a plastic manufacturer has to do is choose an appropriate molding technique.

A good example is the blow molded plastic pallets that are strong and suitable for cold supply chain systems.

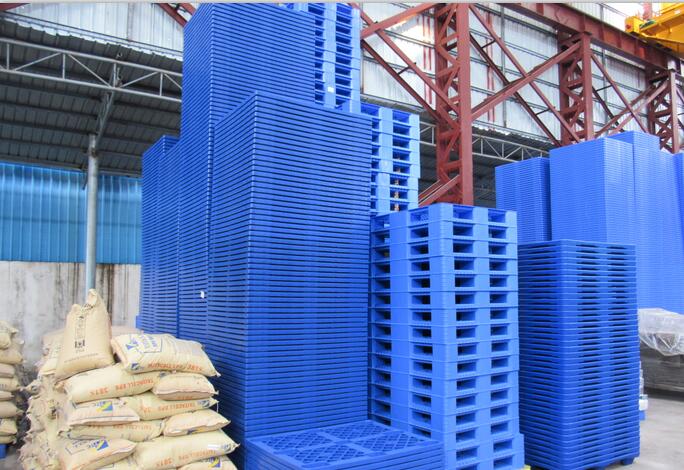

These are heavy duty plastic pallets stacked in a warehouse

Furthermore, for high temperature environments, you need to choose PP material.

It can handle greater weight, thus, suitable for most racking applications.

Normally, the PP plastic pallets are more expensive than the HDPE plastic pallets.

Conclusion

As you can see, plastic pallets play an integral role in product handling applications.

Be it in retail stores, industrial processes or product distribution channels, its only plastic pallets that can meet your specific needs.

At WeePallet, we use different molding technique such as thermoforming, blow molding or injection molding to produce custom design or ISO plastic pallets.

We do a comprehensive research on all applications of plastic pallets in supply chain management to adopt a suitable design and material.

Also, we have adopted strict quality control procedures to guarantee exemplary performance even in the adverse environmental conditions.

For more information about plastic pallets, feel free to contact our technical team.

Further Reading

What is a Plastic Pallet: The Ultimate Guide

The Ultimate Guide to Buying Plastic Pallets (Updated 2017)

Plastic Pallets: A Safe Play for Food

86-137-1715-1153

86-137-1715-1153