Drum plastic pallets play an integral role in oversea shipping. Even though, they share most features with other pallets; there are certain aspects that are unique to drum pallets.

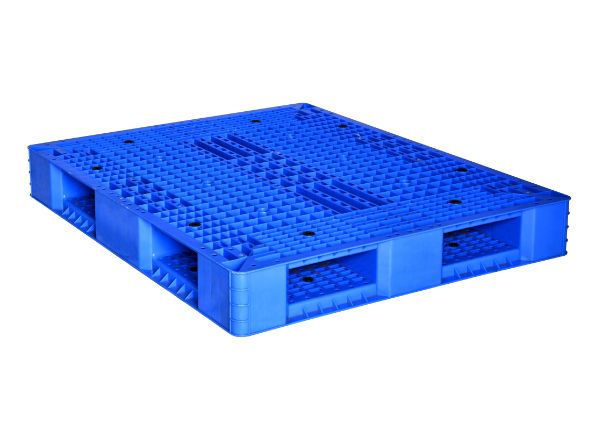

You can have a look at the example below:

Here is an example of a plastic pallet drum

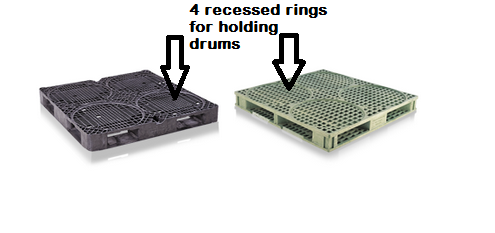

You can compare the above pallet with the general use plastic pallet below:

A plastic pallet without recessed rings for holding drums

Clearly, you can see the difference between these two types of plastic pallets.

The truth is, during the design process, we consider many factors. One crucial aspect is the specific application of the pallet.

Considering that we mold many plastic pallets for various applications, it becomes difficult to choose the right accessory for overseas shipping.

In this article, I am going to teach you how to choose the right drum plastic pallets for your overseas shipping.

Here are the key factors you must consider:

#1: Consider a Drum Plastic Pallet with Recess Rings

Clearly, this is a key feature of gallon drum plastic pallets.

Why do I say so?

As drum pallet manufacturer and supplier, we consider the fact that the load you will lift has a round base. So, we strive to ensure the pallets fit perfectly on the pallets.

Quite a number of our drum pallets have 4 recess rings. However, you may opt for custom plastic pallets with two recess rings.

Remember, it is these recess rings that determine the number of drums a pallet can carry. Below is a good example:

These are plastic pallets with 4 recessed rings each

This implies that, the above pallets can only hold 4 drums at a time.

Ideally, these recessed rings are designed to hold drums securely during shipping and storage. They are designed to stop any possibility of the drum shifting during transportation.

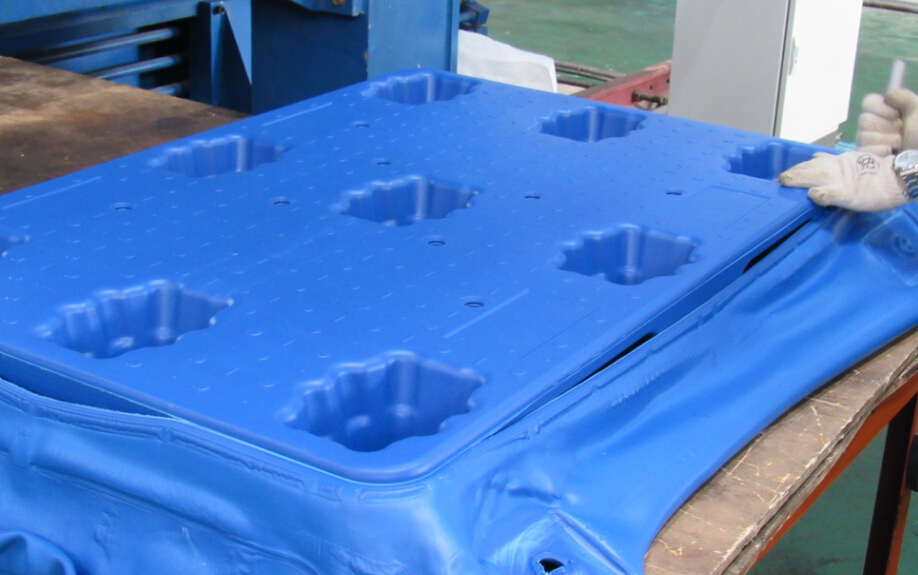

The thickness or depth of the recessed rings of drum plastic pallets will depend on the load. For instance, we have adopted blow molding for drum pallets that can hold 55 gallon drums during shipping, processing or warehousing.

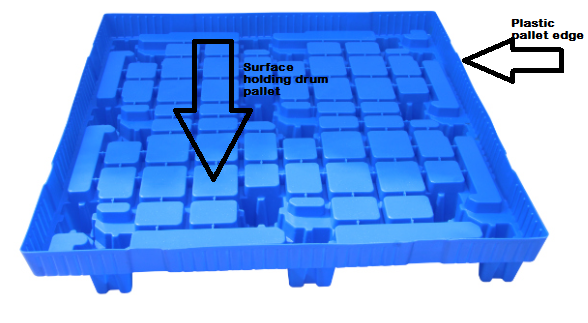

Apart from this, we have another design that you can consider. This can be a perfect alternative during oversea shipping:

A drum plastic pallet

As you can see, this new design is slightly different from the first one. All the four edges of the pallet have section protruding upwards to secure drums from falling.

Apart from this, another aspect to consider when choosing a suitable drum pallet is:

#2: Evaluate the Type of Material Used to Make the Pallet

Why is material an important aspect whenever you’re planning to buy plastic pallets?

Basically, it is the type of material that determines:

- Service lifespan of the pallet

- Load capacity of the drum pallet

- Specific applications

For instance, drum plastic pallets that are used in food processing or pharmaceutical industries must be molded from the FDA approved plastics.

HDPE plastic pallets

Quite a number of standard or custom plastic pallets are made from the following materials:

High Density Polyethylene Pallets (HDPE Pallets)

HDPE is a popular material for making drum pallets. This is due to a wide range of properties such as: Great strength, high tensile strength, corrosion resistant, good dimensional stability and absorbs very little moisture.

As an experienced drum pellet manufacturer, I do recommend the HDPE pallets for in-house or closed loop shipping. That is, use these pallets in the supply chain where the pallets will be returned back to you.

Remember, HDPE drum plastic pallets are durable and they can serve you for several years.

Polypropylene Plastic Pallets (PP Pallets)

First, whenever you opt for drum plastic pallets made from PP material, you should expect to pay more. For instance, a 48×48 inch Plastic Pallets made from PP will be nearly 13% more expensive than HDPE.

This is the reason why HDPE plastic pallets are common in most oversea shipping.

But, why are polypropylene plastic pallets more expensive?

- It is harder and more rigid than HDPE

- PP works at higher temperatures than HDPE

- More suitable for pallets that hold greater weights

- PP is suitable for racking applications

So, how do you choose drum pallet material?

Well, you need a thorough understand of the specific applications in your supply chain. That is, the exact weight you intend to carry and the environment where you plan to use the pallet.

Apart from these, other plastic pallet materials are:

- Blending HDPE and PP; such drum pallets are mainly manufactured from recycled material.

- Advanced composite material; these are cheap pallets that are mainly used to make export pallets – where the manufacturer doesn’t expect to have the pallets back.

Here is what I am saying, choose a drum plastic pallet depending on the task at hand.

As an experienced drum pallets supplier, I will recommend those made from 100% virgin HDPE material. You will be guaranteed of value for your money at all times.

#3: Check the Load Capacity and Size of the Drum Plastic Pallet

We design drum plastic pallets for a wide range of applications. For instance, you may opt for either standard or custom plastic pallets.

This will depend on your specific needs.

For instance, when you review our plastic pallets, you’ll find general use or heavy duty drum plastic pallets.

You should know the following key aspects:

- Pallet size based on its width and length

- Racking, dynamic and static load capacities

Here is what I am talking about:

Specification of plastic pallets

With this information, I am quite certain that you will get drum plastic pallets that suit your unique overseas shipping applications.

Don’t forget to find out whether the pallets are stackable or nestable. This will save you the extra space during return trips or storage.

The last aspect you need to consider is:

#4: Choose a Drum Pallet that is Easy to Handle

By the end of the day, you will load and offload the drum plastic pallets when loaded or empty. Therefore, you need to choose a pallet that is easy to handle either by hand or a forklift.

I find drum plastic pallets with a 4-way fork truck entry and 2-way hand truck entry more convenient and easy to handle. Again, this will depend on the handling equipment.

As a drum plastic pallet manufacturer and supplier, we design every drum plastic to ensure easy handling. That is, their legs are angled creating tapered slots.

With this design, you can use either forklift or jacks.

A man lifting drums on a plastic pallet

Apart from theses 4 critical aspects to consider, always buy drum plastic pallets from a reputable manufacturer. And this is why WeePallet is always ready to help.

Here is an article I wrote about: The Best HDPE Plastic Pallet Manufacturer for OEM Business.

Conclusion

In summary, whenever you’re planning to buy drum plastic pallets, you need to focus on: Unique design (recess ring), load capacity, size, material and ease of handling the pallet. With these, you will get a drum pallet that meets your specific oversea shipping tasks.

More Sources of Information:

- Reusable Plastic Pallet Case Study – Source: Alameda County Waste Management

- Pallets – Source: Wikipedia

- Pallet Safety PM-15 – Source: HSE

86-137-1715-1153

86-137-1715-1153