I know probably, you’re planning to but custom plastic pallets for your supply chain management.

However, stating the right specifications for the plastic pallet is always the most challenging task.

In this simple guide, I am going to highlight all critical information you should tell the plastic pallets manufacturer. This will help the manufacturer to choose the right material, testing procedure and molding technique.

Let’s review these facts, one at a time:

1. Manufacturer Must Know about the Load Carrying Capacity of the Custom Plastic Pallets

Each custom plastic pallet design can only handle a specific amount of weight. This is to ensure that the pallet does not break or get damaged when in use.

The amount of load will depend on the nature of task at hand.

It is important that you specify all the three types of loads. These should include:

· Dynamic Load of Plastic Pallets

It is the maximum amount of load a custom plastic pallet will handle when in motion. That is, the plastic pallet may be in a conveyor belt, forklift or jerk.

The dynamic weight of the pallet is determined when the load is evenly distributed on the plastic pallet surface.

· Static Load of Plastic Pallets

This is the load a custom plastic pallet will handle when at rest.

That is, when you place a plastic pallet on a flat surface and it is not subjected to any kind of movement.

The static load on a plastic pallet is based on an assumption that the load is evenly distributed within the plastic pallet surface.

· Racking or Shelf Load of Custom Plastic Pallet

This is the amount of load a plastic pallet can hold while resting on a racking system.

That is, it is held in position on only two sides.

Here is what I am talking about here:

These are WeePallet plastic pallets showing dynamic, static and shelf/racking load capacity.

With this information, a custom plastic pallet manufacturer will design and mold one that suits your specific needs.

2. Advice the Manufacturer on the Specific Applications of the Customized Plastic Pallets

Whenever you’re buying custom plastic pallets, it means the standard designs available cannot meet your specific needs.

Therefore, you need to discuss this with a plastic pallets manufacturer.

For example, there could be a possibility where you need a plastic pallet for:

- A closed loop supply chain system; since pallets will be returned to you – so go for a HDPE material that is durable and reliable.

- Medicine or foodstuff applications; you need hygienic pallets that are easy to clean and do not hide dirt or dust.

- Shipping pallets; here, you may opt for cheap pallets such those made from recycled plastic material.

In short, you need to be specific as far as the application of your plastic pallets is concerned.

Below is an example of a plastic pallet for specific application:

These are examples of drum plastic pallets.

Perfect examples in this category are the anti-spill plastic pallets for transporting hazardous liquids and drum plastic pallets with recessed rings.

The recessed rings hold the drums in place during transportation or storage.

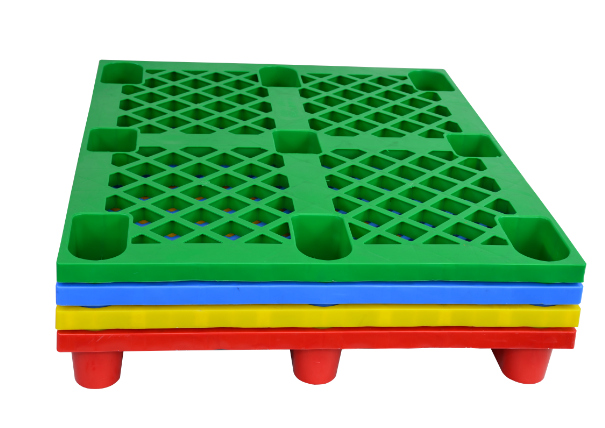

3. Inform the Manufacturer of the Specific Design and Color of the Custom Plastic Pallet

The fact that you need a custom plastic pallet implies that the available options may not suit your business.

In short, your technical team should be ready to collaborate with the company to ensure you have a suitable design.

It should be a design that meets the right specifications of the applications you had listed above.

Once you hire a professional company, they’ll guide you through the entire process.

By the way, have you read my post on The Ultimate Guide to Buying Plastic Pallets (Updated 2017)? You should.

It has important points on how to find the right company (in point no.1).

Such a company will provide all the necessary technical advice alongside CAD drawings where possible.

The easiest way to go about this process is to choose from the available plastic pallet designs and make modifications to suit your specific needs.

Again, I have another useful resource where I covered over 12 different plastic pallet designs.

Ensure you study this: 12 Types of Industrial Plastic Pallets for Supply Chain Management carefully.

It will help you when it comes to making the right decision.

Apart from design, the colors of plastic pallets play a critical role too.

You can choose one depending on the specific needs of your supply chain management system.

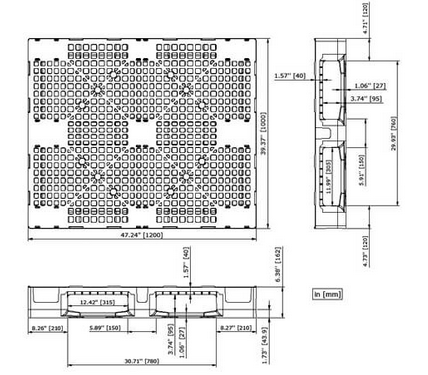

These are 4 different colors of nine legs plastic pallets.

You can choose from a wide range of colors. Remember, you can use color to:

- Reduce loss by matching all your plastic pallets

- Identify pallets

- Designate pallets by their specific functions

In most cases, black or brown plastic pallets tend to be cheap compared to white plastic pallets or any other colors.

This should not hinder you from considering those options.

The bottom line is, custom plastic pallets are durable and can serve you for a long time.

4. Let them Know the Specific Size of Plastic Pallets You Need

You should order for custom plastic pallet sizes that suit your specific applications.

However, in case you’re going to use the plastic pallet for shipping or supply chain that involve other partners, then I recommend the standard sizes.

For instance, the 42″ X 42″ plastic pallets and 48″X48″plastic pallets are common in most industrial setups.

At times, they are regarded as the world standard pallets.

Also, some sizes do vary depending on the specific regions.

Let’s look at a few examples:

- Central Asia we have the 1100mm by 1100mm

- Europe and Asia there are the 1200mm by 1000mm

- Australia uses 1140mm by 1140mm

Of course, these are the most common plastic pallet sizes.

When it comes to North America, there are many standard sizes, depending on the specific industry you intend to use the plastic pallet in. Here are six examples:

Plastic Pallet Size | Recommend Use/Application of the Plastic Pallet |

42” by 42” | Paint and communication equipment |

48” by 48” | Drums |

| 40” by 48” | Cement and military equipment |

44” by 44” | Chemical drums |

| 36” by 36” | Beverage industry |

48” by 36” | Shingles |

NB: You should order for custom plastic pallets with very unique sizes if you’re going to use them for in-house operations.

Otherwise, consider standard sizes.

5. Outline Your Importation/Exportation Regulations and Requirements

With plastic pallets, you don’t have to worry about the ISPM 15 Regulations.

This is because plastic pallets do not require special treatments and inspection.

Still, you should ensure that the plastic pallets are designed and molded to meet the required safety standards.

Therefore, any manufacturing process should conform to the European, American, Australian or Japanese standards.

This is a plastic pallet on a forklift.

This is critical for OEM clients who intend to distribute plastic pallets in certain regions outside their geographical location.

Again, you should purchase the UL-listed plastic pallets. They meet the required fire standards.

Another key aspect that a manufacturer should know is your quest for acquiring high quality plastic pallets.

6. Let them Know Your Commitment to High Quality Custom Plastic Pallets

It is your duty as a customer to ensure you buy a high quality plastic pallet.

To achieve this, your team should work closely with plastic pallet company.

This will ensure strict quality control – inspecting raw material and the final product.

By adopting such a structure, you will be guaranteed of high quality testing.

For example, in the video below, the WeePallet technical team is inspecting the plastic pallet to ensure it meets the right specifications.

If possible, the plastic pallet should pass the following critical quality tests:

- 100 meters drop test; examines how corners react to impact

- Reduced or vacuum tests; important for pallets used in high altitude or air freight

- Durability tests; these include random vibration, bending, compression, creep analysis

- Loading tests; ensure the pallet can handle the dynamic, static and racking loads.

If you’re a distributor or an OEM client, the manufacturer should generate plastic pallet test reports.

Of course, they should work with certified partners such as SGS.

Generally, this will give you a good name, hence a reputable distributor in the plastic pallet industry.

7. Be Clear About Your Budget

Like I said earlier, hiring a professional company to make custom plastic pallets increases your chances of growth and expansion.

Why do I say so?

As a plastic pallet distributor or OEM client, every decision aims to guarantee a reasonable ROI.

This is why buying plastic pallets from the original manufacturer will make an economic sense.

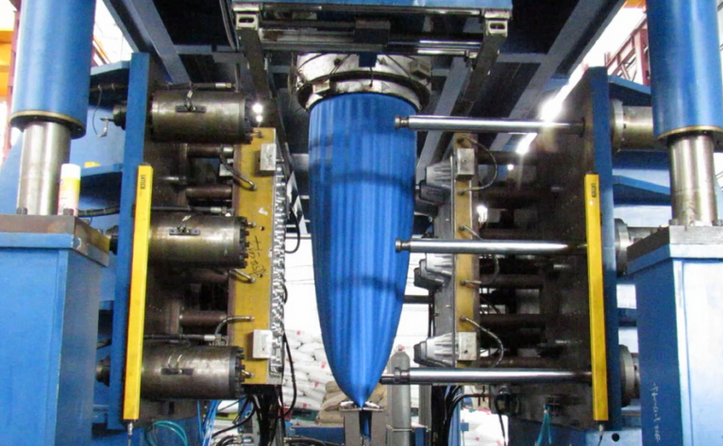

Based on your budget and quantity of custom plastic pallets, you manufacturer will adopt a suitable technique and process.

For instance, it will be impractical to design a new mold on a limited budget.

Normally, plastic pallet manufacturers may choose blow molding, thermoforming or injection molding process.

For example, the manufacturer will opt for blow molding in situations where the custom plastic pallets will be used in extremely low temperatures (-40°C).

Plastic Pallet molding

On the other hand, the manufacturer may opt for thermoforming molding technique where:

- Cost saving is a priority; it comes with a low cost of tooling compared to injection molding hence, affordable plastic pallets.

- Extremely large plastic pallets are needed

- An application requires twin-sheet plastic pallets; they are durable and show no signs of damage when hit by a forklift.

In short, you should give accurate information to get cost competitive custom plastic pallets.

8. Specify the Plastic Pallet Materials You Recommend for Your Products

First, I want you to understand that custom plastic pallets are molded from a range of materials.

However, not all will guarantee optimal performance in the most demanding work conditions.

Second, the type of plastic material will determine the cost per unit pallet.

It is for this reason that you find plastic pallets are more expensive than wood pallets.

However, plastic pallets are cheap in the long-run due to the ability to maintain dimensional stability, prolonged use, high hygiene, exemplary strength, reduced inspections and treatment, just to mention a few.

Assuming you opt for custom made plastic pallets; there are two options – 100% virgin material and recycled plastic materials.

Custom plastic pallets made from recycled materials are affordable than those of 100% virgin material.

These pallets are made from a mixture of plastic material such as high-density polyethylene (HDPE) and polypropylene (PP) among other materials.

Such plastic pallets have varying performance, hence, the lifespan and performance may not be predictable.

This is common when the individual properties of various plastic materials are not properly controlled.

Another option is the custom plastic pallets made from 100% virgin HDPE or PP materials.

These pallets are durable, strong and impact resistant than those made from recycled materials.

However PP plastic pallets are rigid and harder than HDPE plastic pallets. They can withstand high temperature and are designed for heavy load.

This explains why PP pallets are more expensive than the HDPE pallets.

With all this information, I am sure you can budget well for your plastic pallet business.

Apart from this, you need to evaluate the company to understand how they intend to accomplish the project.

9.Your Custom Plastic Pallet Manufacturer Must Explain How they Plan to Accomplish the Task at Hand

It’s interesting that most people don’t put custom plastic pallet manufacturers to the task of explaining how they plan to accomplish this work.

The company should show commitment and seriousness throughout the entire plastic pallet molding process.

That is, they should indicate the source of raw materials and whether they meet the agreed quality standards.

You should request for a document or proof of this.

Again, in case you have to redesign the plastic pallet.

I recommend that you sign a non-disclosure agreement.

This way, you’ll protect your design. You need to work on a framework where the manufacturer allows you to review the sample.

That is, you get a chance to participate actively during the entire molding process.

Always deal with a custom plastic pallet molding factory that is reputable and professional.

This way, you’ll get value for your money.

Conclusion

By following these simple processes, I am sure you’ll get high quality custom plastic pallets molded to your unique specifications.

Be honest and give every detail about the kind of pallets you want, while collaborating with the factory technicians.

In case you’re new to plastic pallet industry or for any questions, you can contact us today.

Further Reading

- Global Pallets Market Analysis – Source: Hexa Research

- Flammability Test for Fire Retardant Plastic Pallets – IAFSS

86-137-1715-1153

86-137-1715-1153