Custom built plastic pallets play a critical whenever you plan to adopt these accessories for unique applications that do not fit the standard specifications and designs.

This requires a careful plastic pallet design and selection of material to fit the unique material handling processes.

By sourcing from a reputable custom plastic pallets manufacturer, you can design unique accessories that play a pivotal role in your marketing and branding needs.

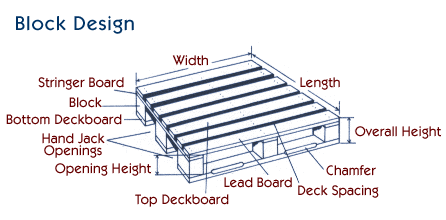

Here is a block design of a plastic pallet. Image source: Robbins Resource Management

In this article, I want to show you how to leverage on the key features of custom built plastic pallets for marketing and branding needs. Here is how to go about this:

1. Source from a Reputable Custom Plastic Pallet Manufacturer

Choosing a company that has specialized in custom built plastic pallets will make the work easy and simple. For instance, at WeePallet, we specialize in custom plastic pallet molding.

This implies; we already have all mechanisms in place to mold plastic pallets as per the unique requirements of all our customers.

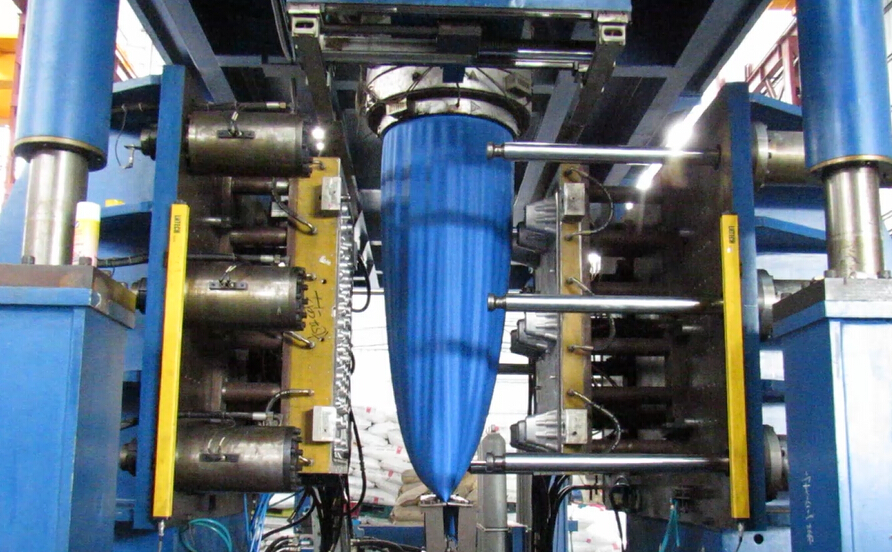

For instance, we have acquired different injection molding, blow molding and thermoforming machines, tooling and accessories.

It doesn’t matter whether you need:

We will simply choose an appropriate custom plastic pallet manufacturing process for your applications. This way, you are always guaranteed of the best market prices.

For instance, we may opt for vacuum thermoforming for small quantity production and injection molding for large quantity plastic pallets.

Of course, adopting a specific process will depend on the specific applications of the plastic pallets.

So, the best way to go about this is doing a random search online. I prefer you opt for plastic pallet manufacturing companies in China.

They offer better deals at the best market prices even for custom made pallets. Here is a blog I wrote on: How to Choose a Plastic Pallet Manufacturer.

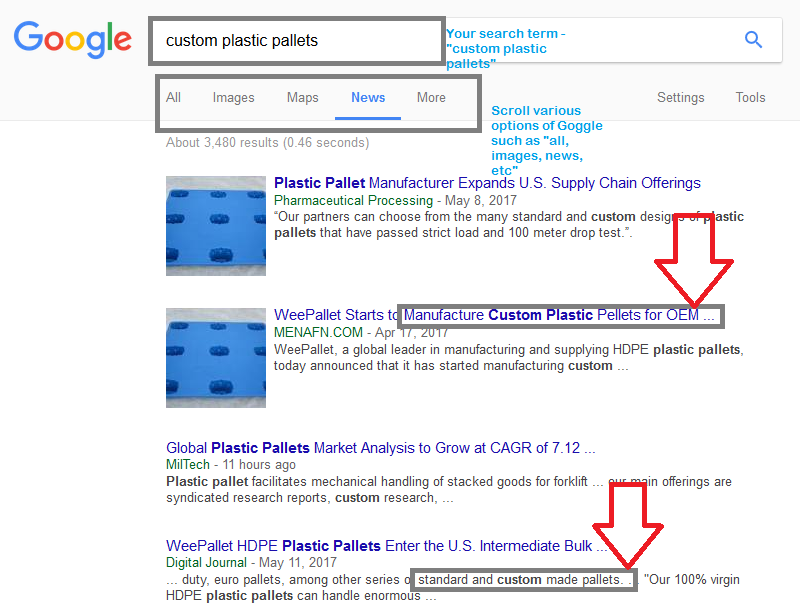

It has all the necessary steps you need to consider in this process. Alternatively, searching for “custom plastic pallets” will give you all the appropriate results you need.

Here is what I mean:

Searching for custom plastic pallets manufacturer

As you can see, this is a simple process.

2. Start Designing the Custom Built Plastic Pallets

You can easily use unique custom plastic designs for branding and marketing needs. In fact, using them as display pallets can at times attract more customers.

So, how do you design the custom plastic pallets?

· Request for a Technical Drawing of the Custom Plastic Pallet

Use the CAD software to draw the plastic pallet. Normally, as a leading custom plastic pallet manufacturing company, we offer all the technical support when it comes to this.

This will enable you to have unique technical drawings of your plastic pallets, depending on the unique requirements of any application.

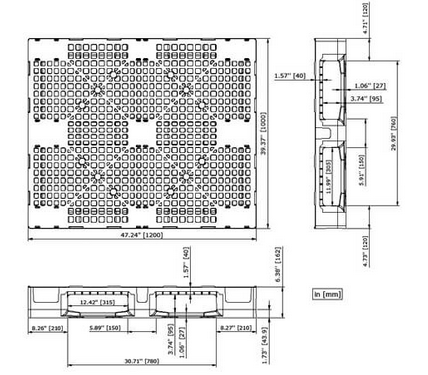

Below is a technical drawing of a plastic pallet:

A technical drawing of a plastic pallet

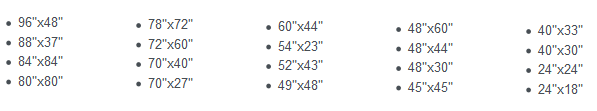

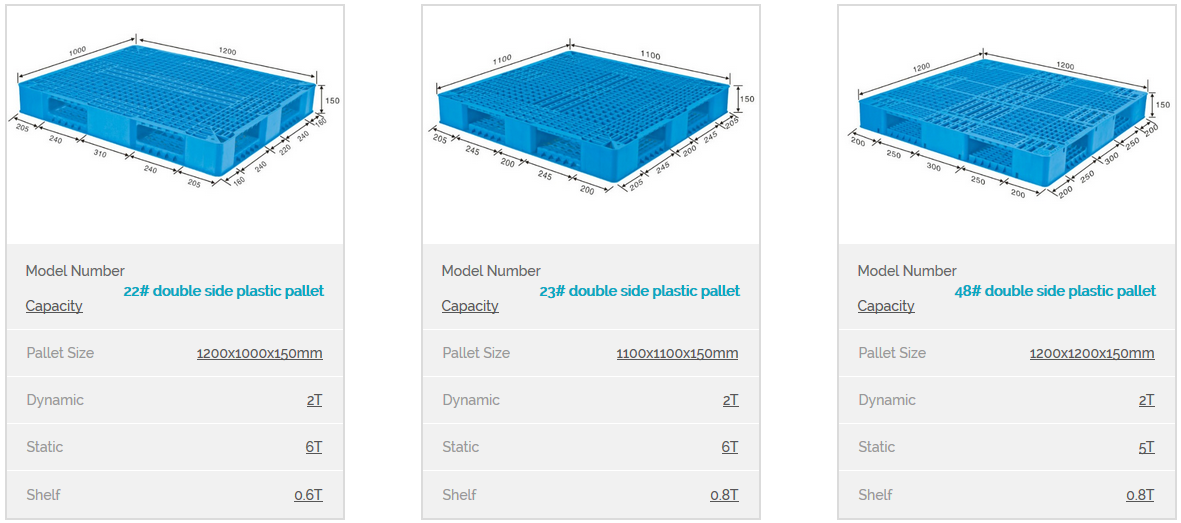

Some of the most common sizes of custom built plastic pallets include:

Different sizes of plastic pallets

Apart from the custom technical drawing and sizes, another critical aspect you need to consider is the specific features of the plastic pallet.

· Specify the Unique Features of your Plastic Pallet

The custom built plastic pallets may have different features for specific applications. It is at this stage that you can include unique features such as company logo, tracking or identification mechanisms.

From experience, I can confidently confirm that the unique features of plastic pallets play a critical role in branding and marketing.

It doesn’t matter whether you need heavy duty, shipping, storage, drum or euro pallets. You can still tweak the features to meet specific needs of your supply chain.

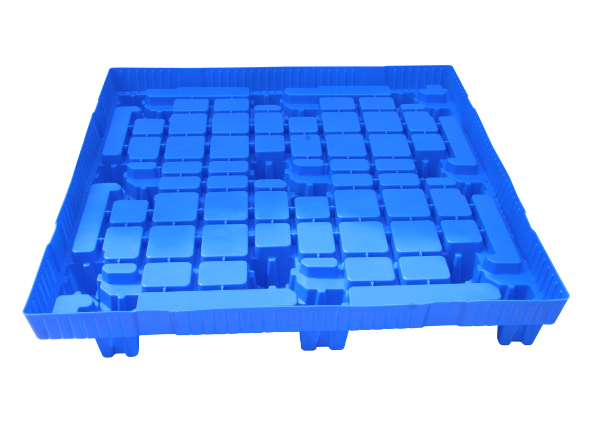

WeePallet Thermoformed plastic pallets designed for different shipping processes

Some of the key features you should consider include:

· Load Capacity of the Custom Plastic Pallets

Custom plastic pallet designs may feature different load capacities. As part of your branding and marketing strategy with your plastic pallets, you should consider the dynamic, static and racking load capacities.

WeePallet double side plastic pallets with varying dynamic, static and shelf loads

Remember, like the standard plastic pallets, they should conform to the required plastic pallet tests standards.

· Recessed Rings

This is a critical feature whenever you are designing drum plastic pallets. The recessed rings are designed to hold the drums in place, hence preventing the chances of it falling during shipping.

WeePallet drum plastic pallet

Follow this link to learn more about How to Choose Drum Plastic Pallet for Oversea Shipping

· Forklift Entry Points

When designing custom plastic pallets, you can choose the 2-way or 4-way forklift entry points. However, the custom plastic pallets with 4-way forklift entry points are easy and convenient to handle.

A plastic pallet with 4-way forklift entry points

· The Right Material for Custom Plastic Pallets

As one of the leading custom plastic pallet manufacturers, we offer two different options:

- Plastic pallets made from 100% virgin HDPE or PP materials; they are durable and long-lasting

- Recycled plastic pallets; they are made from a mixture of used plastic pallets.

Custom plastic pallets made from 100% virgin materials are more expensive than those made from recycled plastic materials. Basically, the guiding principle here should be where you intend to use the plastic pallets.

For closed-loop supply chain, you should go for plastic pallets made from 100% virgin material. However, where the plastic pallets will not be returned, you can use the recycled material.

Apart from these, other factors you should consider when designing your custom built plastic pallets include:

- Additional functionalities such as anti-static, RFID tag, flame retardant, water resistant, dimensional stability, etc.

- Anti-slip property; in the forklift slots, they provide additional grip to forklift handle while on the surface, they provide additional grip to the load.

Lastly, you can choose from the numerous surface designs that can handle the dynamic, static and shelf loads.

3. Work Closely with the Custom Plastic Pallet Manufacturer

Cooperating with the custom plastic pallet manufacturer will ensure this accessory is made to the right designs and specifications.

That is, you should deliberate on adopting an innovating and creative design for the plastic pallets.

This way, even if you are an OEM client, your custom plastic pallets will definitely standout hence, the ability to compete favorably in the market.

Furthermore, you should adopt a state-of-the art molding equipment that guarantees efficiency and reliability in the entire processes.

The truth is, whether you’re looking for stackable custom plastic pallets or rackable plastic pallets; designing one is always the most challenging process.

This is why I recommend that you work closely with a professional and experienced plastic pallet manufacturer.

This is the reason why WeePallet is here for you.

Conclusion

You need to choose a custom built plastic pallet depending on the unique needs and applications in the supply chain management system.

With this, you will improve the efficiency and reliability at every stage – be it shipping, storage or in-house transportation.

This will give your business a good name, hence, making branding and marketing easy.

For custom built plastic pallets, you can contact us for advice or any inquiry.

86-137-1715-1153

86-137-1715-1153