Do you handle heavy duty loads, use high rack warehouses or automated product handling mechanism?

Well, I want to share with you may 10 years’ experience on the basic factors to consider before buying heavy duty plastic pallets. I will not only state these 7 essential factors, but also show you why they are important.

What exactly am I talking about?

1. Insist on Buying Heavy Duty Pallets Made from 100% Virgin HDPE Material

Unless you need an extremely tough plastic pallet made from polypropylene (PP) material, I believe a high density polyethylene (HDPE) pallets will serve you well.

With HDPE heavy density plastic pallets, you’ll definitely get value for your money. That is, as long as you use them in a closed-loop supply chain.

Heavy duty plastic pallet

HDPE material is strong, durable, sturdy, dimensionally stable and absorb very little amount of moisture. This implies, these pallets will serve you for a long period of time, hence saving money in the long-term.

They are precisely designed and molded to handle all possible loads in industrial setups. That is, it can handle loads ranging from:

- Dynamic load – 500 to 5,000 kg.

- Static load – 600 to 4,000 kg.

- Racking load – 500 to 1000 kg.

These loads may vary depending on whether you opt for standard or custom plastic pallets. I know if you’re new to plastic pallets industry, the above information may seem ambiguous.

Don’t worry, I’ll explain:

Static load: It is the amount of load a pallet can hold at a room temperature (about 20°C), when the load is evenly distributed on its surface.

Racking load: This is the load a pallet can hold when resting on two supports at a determined height and room temperature (about 20°C), assuming the load is evenly distributed.

Dynamic load: The maximum amount of load a pallet can handle on a forklift at room temperature (about 20°C).

In some extreme situations, we may reinforce the HDPE plastic pallets to accommodate more weight. However, this will depend on the nature of the task at hand.

Feel free to share with us the circumstances which you intend to use the heavy duty plastic pallet.

2. Understand the Plastic Pallet Manufacturing Process (A Brief Information is enough)

I certain, this has come as a surprise to many.

This doesn’t imply that you should come to our plastic pallet manufacturing plant to know exactly what we do. No, that’s not what I mean.

The truth is, normally, we adopt a specific plastic pallet manufacturing process depending on the specific needs of our customers.

Broadly, you may opt for injection molded, blow molded or thermoformed plastic pallets. Well, these are good manufacturing techniques, however; every process has its strength and weaknesses.

Let me give you a clear comparison based on my research:

Normally, we can use thermoforming when you need twin sheet plastic pallets. Besides, the vacuum thermoforming process is affordable.

However, a major drawback of this process is the thin walls of plastic pallets and its low cycle time. Therefore, you can only use it for small batch production.

Blow molded plastic pallets are popular for high strength and high production. Moreover, such heavy duty pallets are suitable for supply chain in cold environments.

They are super strong, available in robust designs and to withstand heavy weight.

As you can see, the manufacturing process of a heavy duty plastic pallet will help you opt for a cost competitive option that guarantees unmatched performance.

3. Ensure the Heavy Duty has Anti-slip Top Deck

I want you to review these three plastic pallets:

Plastic pallets with anti-slip structure

Clearly, it is quite clear that the surface is made such that it eliminates the possibility of the heavy load slipping of the pallet. This is an important safety measure.

Another example is the heavy duty drum plastic pallets. You’ll find that all drum pallets that carry a load of 55 gallons have recess rings to hold the drum in position.

Heavy duty drum plastic palled with recessed rings

From experience, a heavy load falling off the pallet may cause serious damage to the product. This can at times translate to huge losses.

I don’t want you to be a victim. So, don’t forget; anti-slip is necessary.

4. Choose a Durable & Dimensionally Stable Heavy Duty Plastic Pallets

At times, I get surprised when clients deliberately decide not to ask for plastic pallet quality test results. This is wrong.

As a client, you need to ensure the heavy duty plastic pallets are subjected to the required quality tests. This is the only way you’ll be sure that the pallets is sturdy, durable and dimensionally stable.

You can know this by looking at a plastic pallet. It is important you use the test results to analyze a pallet. Below is a video of quality inspection of a quality of a plastic pallet.

Remember, the fact that a heavy duty plastic pallet is made from 100% virgin HDPE material is not enough. The overall structure and design play an integral role here.

This is exactly what you should focus on since it will tell how long the pallet will hold heavy load and withstand multi-use.

5. Consider the Ease of Handling the Heavy Duty Plastic Pallet

You need to consider the entry and exit points of a forklift in the pallet. With this, you will handle the heavy duty plastic pallet easily.

Besides, you don’t have to worry about the forklift damaging the plastic pallets. Remember, a HDPE plastic pallet is designed to serve you for more than 7 years.

So, should you opt for two or four way pallets?

This is a common question my clients ask me every day. Let me make this clear:

Two-way Forklift Entry

This is where your forklift can enter the heavy duty plastic pallet either from the front or rear. The plastic pallets are durable, economical and provide greater strength than most four-way forklift.

Here is what I am talking about:

A 2-way forklift entry

However, the main challenge with these pallets is lack of maneuverability with regard to forklift entry. For sure, it may become a challenge during storage and freight.

Four-way Forklift Entry

The design of this plastic pallet is that the forklift can enter the plastic pallet at either end or both sides. This allows for greater maneuverability within the storage or distribution system.

A 4-way forklift entry

Furthermore, heavy duty plastic pallets with four-way forklift entry are uniquely designed to handle heavy loads.

Apart from these, ensure both the entry and exit points of the pallets are tapered. This prevents possible damage on the pallet during handling.

6. Know the Size of Heavy Duty Plastic Pallet (Pallet Dimensions)

Apart from the weight we expect plastic pallets to carry, dimensions play an integral role here too.

That is, the height, width, height, thickness and weight of the heavy duty plastic pallet. Here is an example of plastic pallet dimensions:

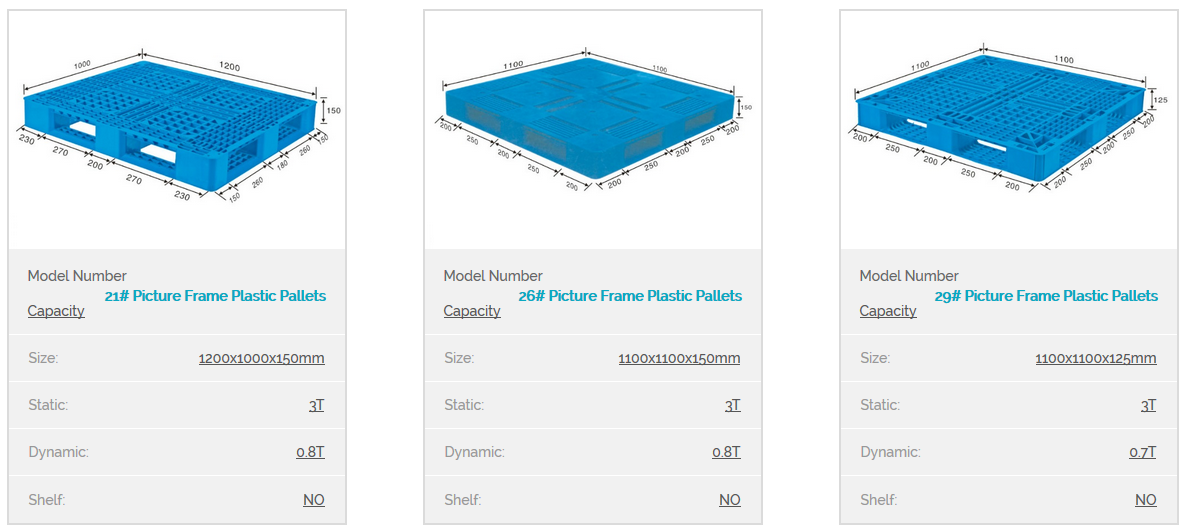

Specification of plastic pallets

Although these are standard dimensions, you may opt for custom heavy duty plastic pallets. These dimensions may vary depending on the geographical location.

For example, the 48×40 plastic pallets are common in North America. Therefore, as you order for these pallets, you need to consider the following:

- Dimensions in both mm and inches

- ISO standard

- Region/geographical location

- Type of industry

For instance, the 48×40 plastic pallets are mainly designed to carry drums – also called the drum plastic pallets.

7. Consider Stackable or Rackable Heavy Duty Plastic Pallets

Space is always limited and I am sure, it is the desire of every business owner to save shipping costs.

Maybe this can be a better option for you. But, what do these two terms mean in the plastic pallet manufacturing?

I’ll explore them shortly:

Rackable Heavy Duty Plastic Pallets

These pallets have runners or picture frame bottom, thus, the pallets can be placed safety on the rack top. At times, they are also referred to as picture frame plastic pallets.

Picture frame plastic pallets

Rackable plastic pallets come in three main configurations: Three-runner, picture frame or picture frame with a crossbar. They are generally strong, durable and stable due to this reinforcement.

Remember, by storing a load unit above the floor, you will save more space on the floor.

Stackable Heavy Duty Plastic Pallets

Stackable plastic pallets allow multiple or double stacking of pallets thus saving space during shipping and storage. They come in different configurations such as: 3-runner, picture frame with cross bar or picture frame.

Stacked plastic pallet

Like the rackable heavy duty plastic pallets, these pallets are durable, strong and dimensionally stable. A reason why I recommend them for closed loop or returnable supply chain.

Apart from the 7 factors I have listed above, choosing the right manufacturer is also a critical aspect you can’t ignore. That’s why WeePallet is always there for you.

I know this may seem too complicated a situation if you’re new to plastic pallets industry. Don’t worry, that’s why I am here to help.

Conclusion

As you can see, choosing a durable and reliable is not that obvious. You need to analyze and evaluate critical aspects of the aspects such as rackable nature, forklift entry, manufacturing process, type of material, etc.

In case this seems overwhelming, don’t hesitate to contact me.

86-137-1715-1153

86-137-1715-1153