Blow molding and injection molding are processes you can use to manufacture plastic pallets. Of course, each process has its unique pros and cons.

However, in certain industrial applications such as in cold temperatures, blow molded plastic pallets have proved to be durable and reliable.

So, why is this so?

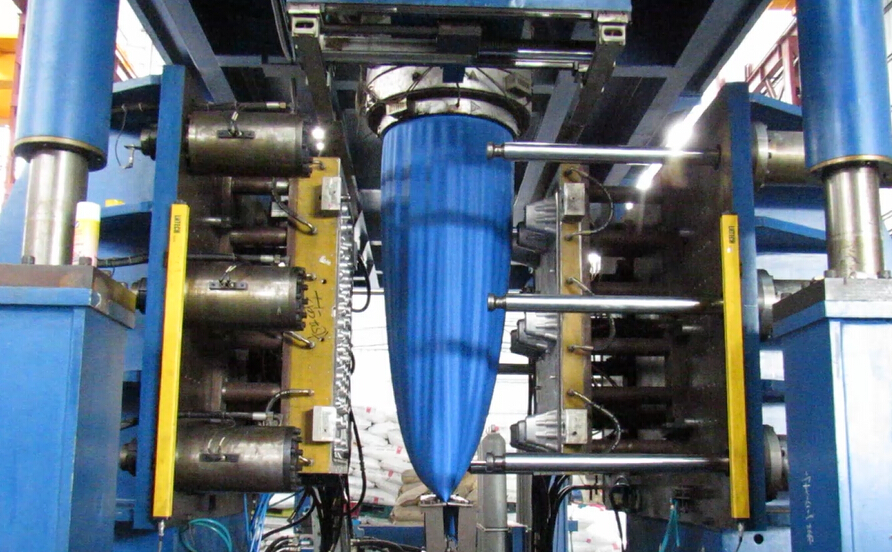

1. Unique manufacturing process

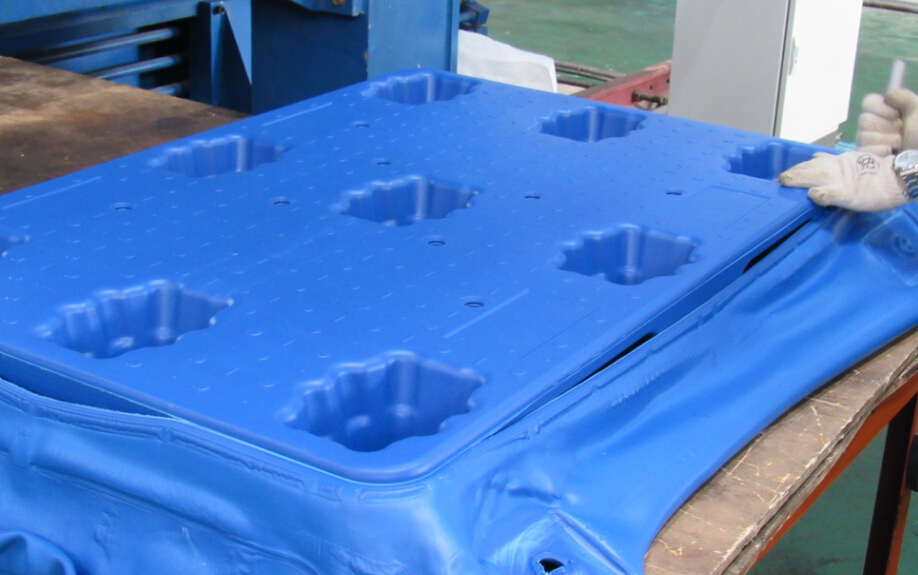

Blow molded plastic pallet feature a unique manufacturing process. That is, you use air pressure to inflate the plastic into the mold cavity.

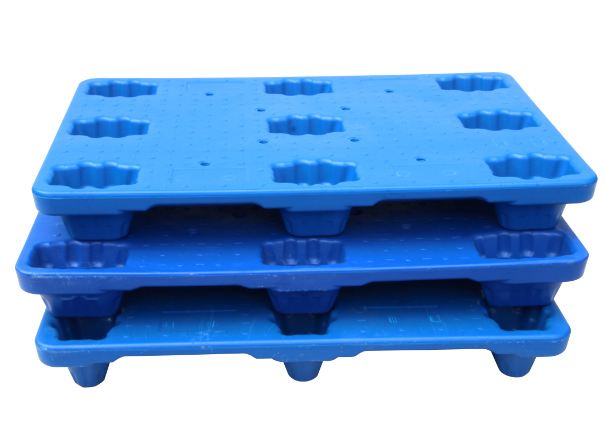

Normally, the plastic pallet looks like a twin-walled thermoformed pallet. In fact, they share a number of physical and performance properties with the twin-walled thermoformed pallets.

For this reason, you can adapt these plastic pallets to a wide range of industrial applications, especially in very cold environments.

This manufacturing process is completely different from that of injection molded pallets.

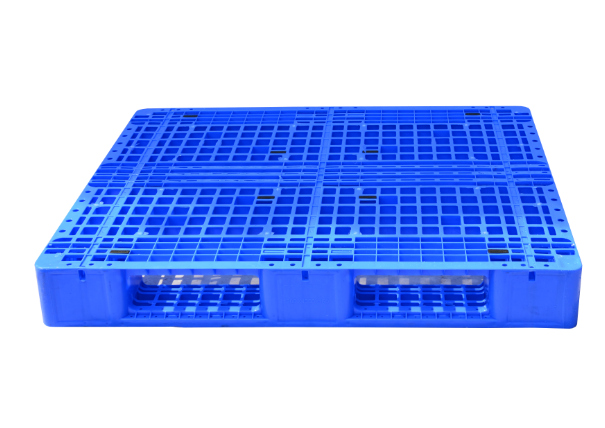

2. High load capacity

This is yet, another fundamental feature of the injection blowing process. These plastic pallets are designed for large voluminous loads. The static load may vary between 4 to 5 metric tons, with the dynamic loading ranging from 2 to 3 metric tons.

Of course, all these are attributed to the ability to control their wall thickness (uniform), of the plastic pallet during the manufacturing process.

3. Resistance to impact

The impact causes wear and tear when loading or offloading plastic pallets. At extremely low temperatures, the damage can be extreme.

However, for these pallets, they will still maintain their structural integrity and strength. A reason why they are highly recommended for use in very cold regions (winter).

It doesn’t matter whether you subjected them to rough handling, rolling or throwing. Their impact strength is almost twice that of injection molded pallets.

4. Extremely resistant to low temperatures

You can confidently use blow molded plastic pallets in very cold temperatures – as low as -40 degrees centigrade. These pallets will never disappoint you.

5. They do not get damaged easily

In most cases, these plastic pallets show no or very little damage when hit accidentally by forklift during loading and offloading.

Moreover, they rarely show signs of wear and tear even after a long period of usage. This a clear manifestation of their durability over injection molded pallets.

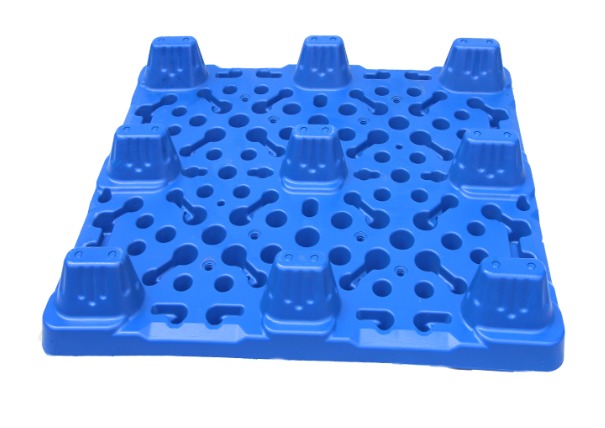

6. Adaptable to any environment

The blow molded pallet can be used in very cold and relatively warm environmental conditions. In most cases, they’ll rarely disappoint. Furthermore, they are resistant to aging, corrosion, moisture and oil.

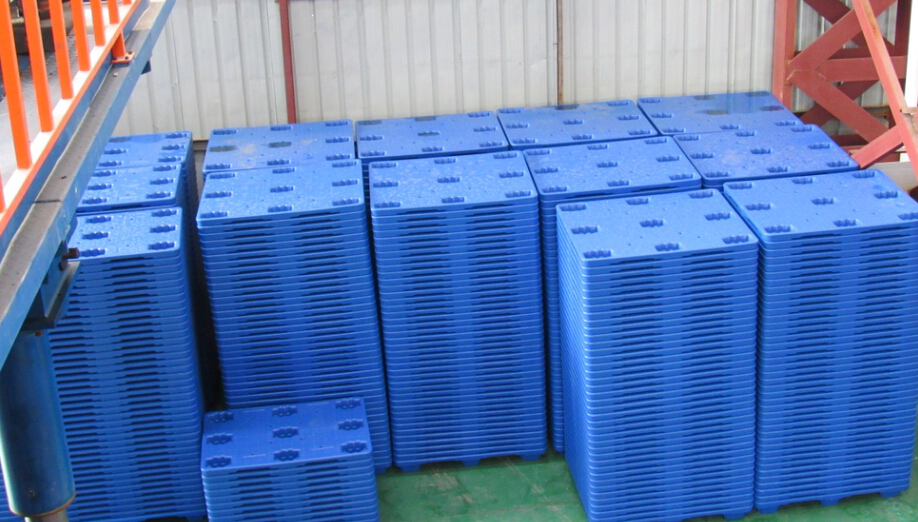

7. Longer service life

Normally, these plastic pallets will serve you for 5 years more than the average plastic pallets. Of course, this is basically attributed to the key features listed above.

This will guarantee long-term cost saving depending on your industry.

Apart from these key seven factors, blow molding plastic pallets are also considered durable due to:

- Super quality and high density resin – HDPE material. It is tough and durable.

- Choice of high quality blow molding machine. It ensures consistency in thickness and even distribution of air during the molding process.

- Unique designs and shapes that guarantee efficiency

Conclusion

WeePallet blow molded plastic pallets are durable with robust designs and that can be adapted to any application. Also, they are dimensionally stable and are molded from high quality virgin HDPE material.

Any questions ,contact our support team now !

86-137-1715-1153

86-137-1715-1153